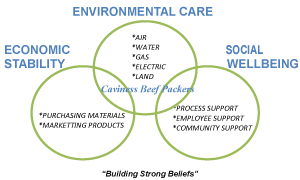

ENVIRONMENTAL CARE – LAND MANAGEMENT

Feasibility: We believe in being good stewards of the land. We utilize land to encompass many facets of our business and we continue to monitor the land as we utilize it. Currently the plant site consist of an area of 700+ acres and it consist of a harvest production area, fabrication production area, rendering area and hides area, along with a truck shop, lagoons and farm land.

*As innovations and technology grows so does our plant, up to date and modernized facility.

*Included in our landscaping is trees and grass that have been planted in the front and sides of the plant.

ENERGY CONSERVATION

Gas Conservation: Caviness Beef operates a slaughterhouse, fabrication, hides and rendering complex that generates waste water that is later used in the production of a bio-gas, by utilizing methane in place of natural gas, we are conserving today’s energy for tomorrows use. Other processes generating waste water include sanitation, cooling water, cleaning out pens, and truck washout.When planning out designs for this new constructed plant, plans were implemented to capture methane and produce a biogas to fire a boiler for hot water use.

Methane, the main component of biogas, is generated during the naturally occurring decay of organic materials in an anaerobic(oxygen-free) environment. This process involves the following three steps;

*Hydrolytic bacteria convert complex organic matter into dissolved compounds with low molecular weight.

*Acidogenic/acetogenic bacteria convert the dissolved compounds into organic acids and hydrogen.

*Methanogenic bacteria finally consume these acids or hydrogen to generate methane and carbon dioxide.

Biogas, which normally contains approximately 74% methane coupled with a heating value of approximately 740 Btu/ft3, can be used to produce energy. At Caviness, the biogas produced from 4 anaerobic lagoons is captured by placing a floating impermeable cover over the lagoons, sealed at the edges to prevent the influx of air. Captured biogas will be conveyed via a pipeline to the facility to fuel one boiler. Gas that is not used for energy production is flared to comply with permit requirements and reduce methane emissions and odor.

AIR QUALITY

Odor Control: *Controls are placed to absorb odors and treat gases.

*We have installed air scrubbers that control odors and treat gases in our system before it releases the air into the environment.

*We take pride in cleaning and controlling the odor from our process.

WATER CONSERVATION

Modern Conserving

In today’s world, innovation must be a part when conserving water. Caviness believes we need to save all the water we can along with all other natural resources. We understand how important water is for this community and this is why we take care of it.

*100% of the water used (waste water) at the plant is recycled back to farm land to grow crops.

Heating Water: *Save energy through use of heat exchangers installed in our system

*This innovation allows us to combine hot water with steam. This will allow us to heat up the water instantly as the overall plant may need.

RECYCLE PROGRAM

Cardboard and Pallets: *All outgoing corrugated boxes and bins are approved for recycling.

*Goal to reduce incoming and outgoing corrugated material footprint.

*Increase use of reusable plastic pallets in place of wood pallets.

*Recycle aluminum cans, recycling motors, recycling oil, recycling plastic containers, recycling process equipment and recycling junk metal.